Despite this apparent need, finding a business application that is both comprehensive and cost-effective can be remarkably difficult.

A basic accounting package is a natural starting point for many businesses looking to make their business operations simpler and more efficient. But in time, these companies develop an overreliance on static spreadsheets and limited accounting systems.

The relatively low cost of maintaining the solution masks costly inefficiencies in critical areas of the business. And all too often, manufacturing teams end up layering on additional pieces of software to try to mask deficiencies in areas such as warehouse or inventory management. This snowball of point solutions ultimately leads to a higher total cost of ownership compared to what manufacturers would face if they consolidated under one system.

As businesses accelerate their growth, the operational problems only intensify. And when challenges arise—and they always do—a collection of software tools that don’t communicate with each other simply doesn’t cut it. How can manufacturers on basic accounting packages handle supply chain disruption, multiple dispersed subsidiaries, or changing rules and regulations?

Switching to NetSuite allows companies to lower costs, simplify key business processes, boost productivity and be more competitive.

Accounting is just one element of a company’s operations, and while most accounting packages are successful at what it does, it will never be much more than a general ledger that doesn’t hold up under increasing business complexities. While it can handle invoices, bills and cash flow tracking, they fail to offer the industry-level granularity that manufacturers need to run efficiently. NetSuite, on the other hand, provides end-to-end visibility into receivables and payables. Businesses are able to automate the entire order-to-cash process and simplify both the procure-to-pay and record-to-report processes. NetSuite also provides real-time insights with pre-built, easily customised financial reports plus views into budgeting, expense allocations, and amortization.

NetSuite’s benefits don’t stop with the accounting function either. Companies can run manufacturing-critical operations like inventory management, order fulfillment, shop floor automation, and warehouse management on the same platform and in real-time. Execute crucial front-office activities as well, such as customer relationship management, support, and omnichannel commerce. And since everything is hosted on the same cloud platform, there is no fear of errors in reporting or lagging data. Information is always up to date.

Source: TechValidate Survey 2021

SuiteSuccess is the culmination of a multi-year effort to combine NetSuite’s unified suite, more than 20 years of industry-leading practices, a new customer engagement model, and business optimisation methods into a unified, industry cloud solution.

SuiteSuccess is engineered to solve unique industry challenges that historically have limited a company’s ability to grow, scale, and adapt to change. NetSuite recognises that every manufacturing business is unique and that one size does not fit all. Unlike most standardised solutions, the NetSuite team works to identify unique business needs and offers customisations to address them. After all, every organisation has a different starting point, business model, and direction moving forward.

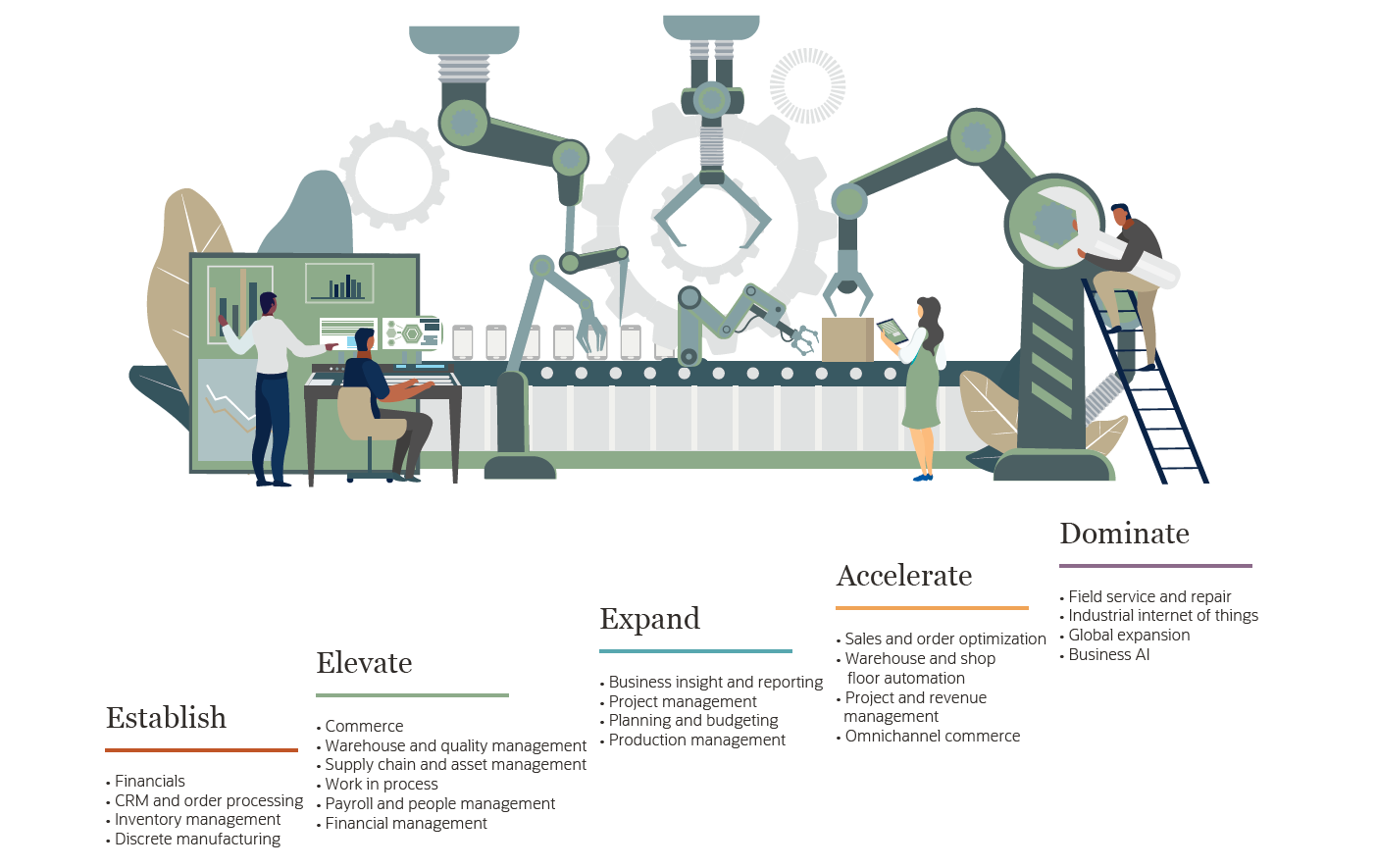

NetSuite has a staged implementation approach so that manufacturing businesses aren’t taking on more capability than they need. Companies establish the foundation with NetSuite’s core financials, inventory management, and discrete manufacturing tools. As they grow, those same companies can expand on their ERP functionality by layering on more robust capabilities. This stairway approach ensures that manufacturers of all sizes and stages are getting a cost-effective solution.

Regardless of where they are located on the implementation stairway, NetSuite gives manufacturers a full set of reports and KPIs to make decisions with. Keep track of basic metrics like inventory turnover and revenue growth but also keep tabs on industry-specific measures like fill rate, yield, schedule attainment, and throughput. The insights that individuals see when they log into NetSuite vary by position too. With role-based, customisable dashboards, a warehouse manager and a sales director can each ensure that they are receiving the reports that are most important to their job functions.

There are an increasing number of companies that have migrated to NetSuite and shown demonstrable benefits as a result.

NetSuite’s automation and artificial intelligence capabilities free up the finance and operations team’s time, allowing them to focus on revenue-generating strategic projects. This allows manufacturers to scale while keeping headcount constant.

Use NetSuite to forecast demand and anticipate when it’s time to order. Auto calculate reorder points and stocking levels based on historical precedence. In the face of supply chain uncertainty, it is crucial that manufacturing teams have a solution that can forecast how much inventory to purchase down to the SKU level.

ADDRESS: Suite 3, Level 1/130 Saint Georges Bay Road, Parnell, Auckland

PHONE: +64 9 531 5777

EMAIL: sales@verdegroup.co.nz

MOBILE: +64 21 144 8590